DALLAS, Ga. — The deadly Titan submersible accident has raised questions about the craft’s carbon fiber hull that failed under 13,000 feet of ocean water.

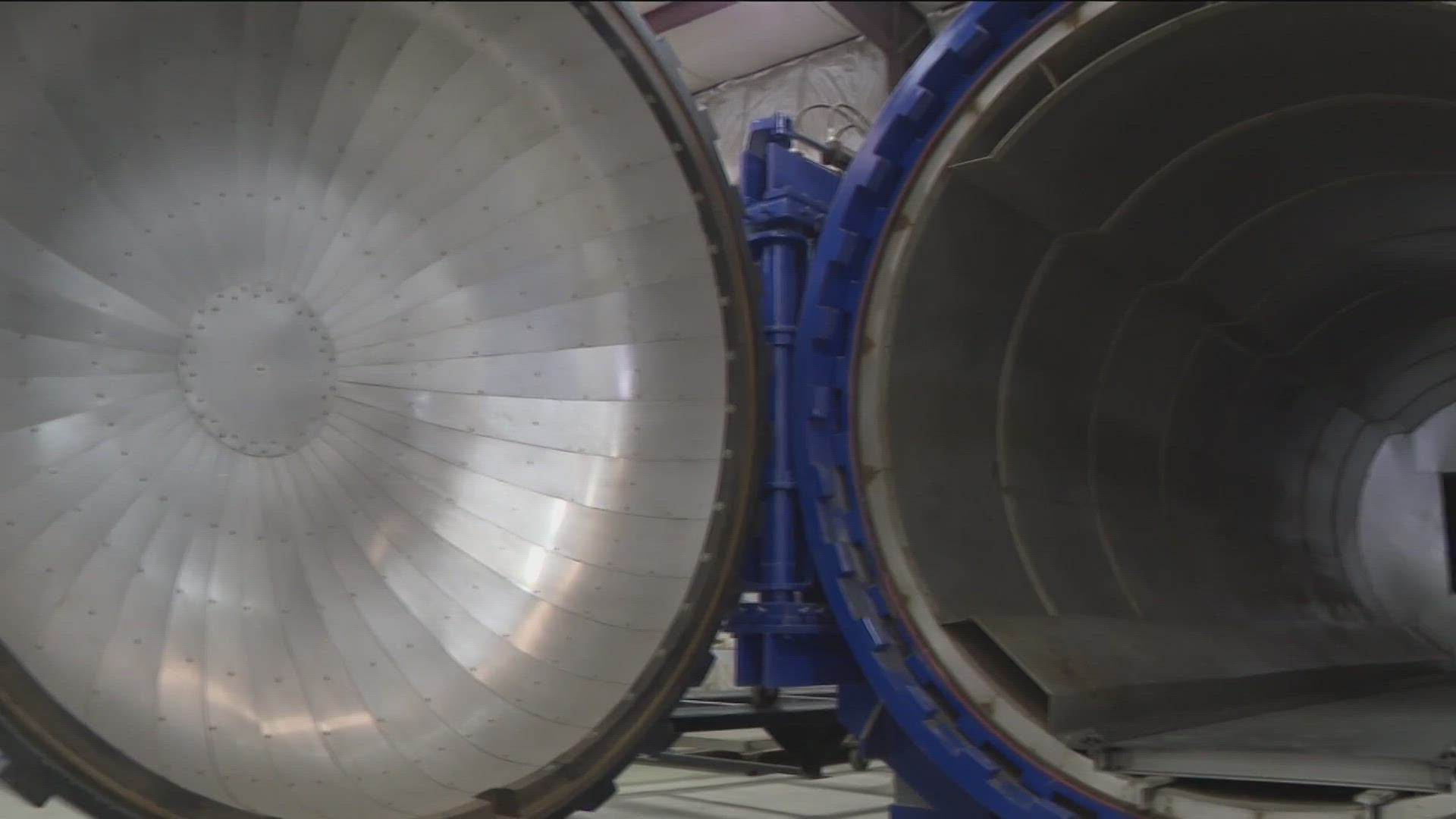

Carbon fiber is at the core of an aerospace engineering and manufacturing business in Paulding County called Top Flight Aerostructures.

"The nice thing about composites is that they are the latest, greatest space-age material, and carbon fiber leading the pack," said Greg Kress, the company’s co-founder. Kress is also an engineer and instructor and a big believer in composites – like those used in commercial aircraft – and used in the doomed Titan submersible.

Kress showed a fibrous cloth stored in a freezer. To create the space-age material, the cloth is bound with resin and superheated in a two-story tall oven – yielding material that’s strong and aerodynamic.

Kress says the Boeing 787 Dreamliner is made out of carbon fiber, as are portions of the Airbus A-350. Both are commercial airliners.

But Kress says it also requires rigorous inspection.

"Any kind of a scratch or a gouge or a hole is going to cause a stress concentration (on the material)," he said. That issue is exacerbated if it’s going to be used under hundreds of feet of water with people inside of it.

"It’s not considered rocket science to inspect it. It’s nondestructive inspection using ultrasound. It’s the same kind of ultrasound used by the medical system to see what’s going on inside your body," he said, adding that an ultrasound inspection of the Titan would have cost about $20,000 – cost-effective, he says, especially if passengers are paying hundreds of thousands of dollars for a ride to the bottom of the sea.

"Nondestructive inspection is not a rarity in the world of composites. It’s what we do all the time," Kress said.

Kress says carbon fiber has proven its value as a space-age manufacturing material. The Titan accident has proven the value, he says, of rigorous testing.