ATLANTA — The future of space travel just got a boost thanks to one Georgia Tech undergraduate student. Dalton Luedke is a third-year aerospace engineering student at Tech, and also part of the NASA Pathways Internship Program.

This summer during his internship at NASA Marshall Space Flight Center, he accomplished a feat that one day could be "out of this world."

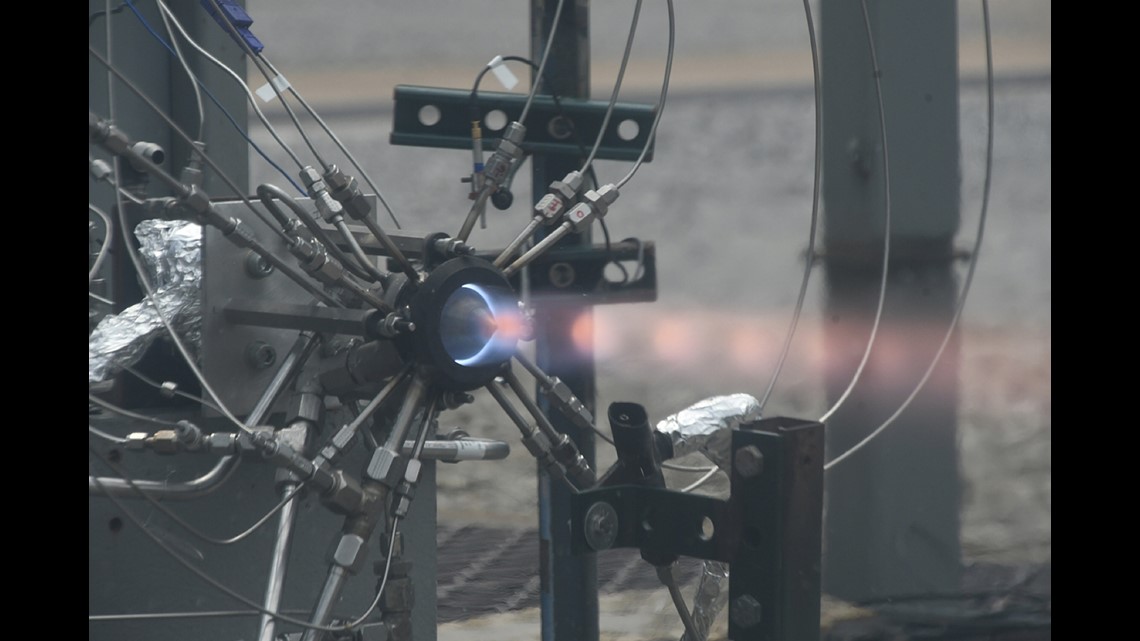

He designed a new rocket engine.

MARLEN, which stands for Maturation of Additive Really Little Engine -- is the new, small version of Luedke's new detonation engine design. "I thought the name was funny, because Marlen is a big fish," Luedke chuckled.

This small prototype engine kickstarts the testing of a new way of space travel. Current space missions use big constant-pressure engines. Think of the classic cylindrical rocket boosters lifting off with the final countdown. But Luedke’s design utilizes a different type of thrust for the rocket engine with a supersonic combustion process called detonation. This new design produces more power with less fuel.

And in his design, the cylindrical boosters were shrunk down to a ring. This provides a reduction of around 70% in length, which weighs much less. In turn, it becomes much more fuel-efficient.

“Think of it like putting a really efficient hybrid engine in a truck without losing the power of the truck,” Luedke explained.

Rocket engines are huge. But Luedke's MARLEN design is a smaller version of this technology. This allows for NASA and partners to test it much more easily, quickly, and efficiently.

"Because it's so small, we'll be able to replicate every component of the engine easier and test many configurations to see what is the most ideal for maybe one day going into space," he said.

One facet of this new engine that Luedke already had a connection to was the building process. In the acronym MARLEN, A stands for Additive. This describes the building process using 3D printers. He already had experience with this technology through the Aero Maker Space at Georgia Tech, and through his family's business, Derbocity, that he created with his dad a decade ago.

During the 3D printing process, three-dimensional solid objects are made from a computer file. The printer adds layers of material (resin, plastic, or in this case metal), giving you exactly the shape and structure you need. The engine prototype Dalton designed was built using an industrial 3D printer that used lasers to fuse together metal powders.

On the first test of his engine, they ran into a speed bump. But they quickly readjusted, and on test number two... it worked.

“It was really exciting and awesome to see," he said. "Not only that it worked, but that our clear configuration also worked, so we could observe what was happening."

It was even more thrilling for his NASA colleagues -- including some who’ve been with the organization for decades. “They were all very shocked [with excitement] and very happy”

When could MARLEN's design soar into space?

“Hopefully within the next decade or two. But first, we have to test it more, write some papers, and test it even more," said Luedke.

A modest answer for a small fish making a big impact in the big sea of aerospace engineering.